Principle

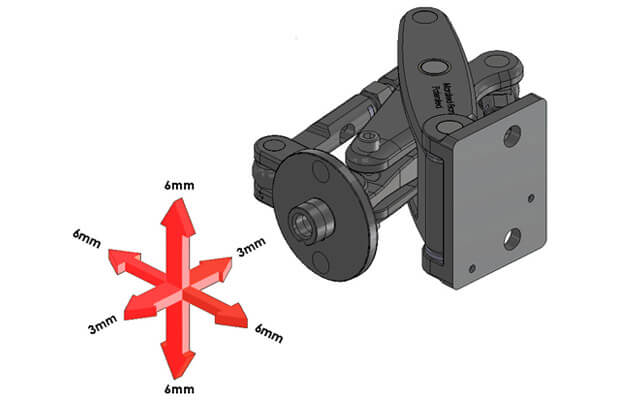

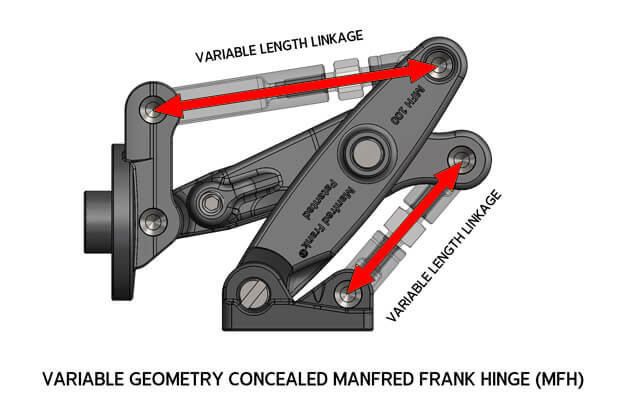

Manfred Frank hinges feature an ingenious and unique principle, which is protected by worldwide patents. Panel alignment is achieved by altering the distance between pivot points, which in turn varies the hinge geometry. There is no need for any lifting or support equipment. With only a spanner or a hex ball nose key (depending on the hinge model), a single person can easily align even the largest door panels instantly and precisely under full load.

Manfred Frank hinges feature an ingenious and unique principle, which is protected by worldwide patents. Panel alignment is achieved by altering the distance between pivot points, which in turn varies the hinge geometry. There is no need for any lifting or support equipment. With only a spanner or a hex ball nose key (depending on the hinge model), a single person can easily align even the largest door panels instantly and precisely under full load.

Range

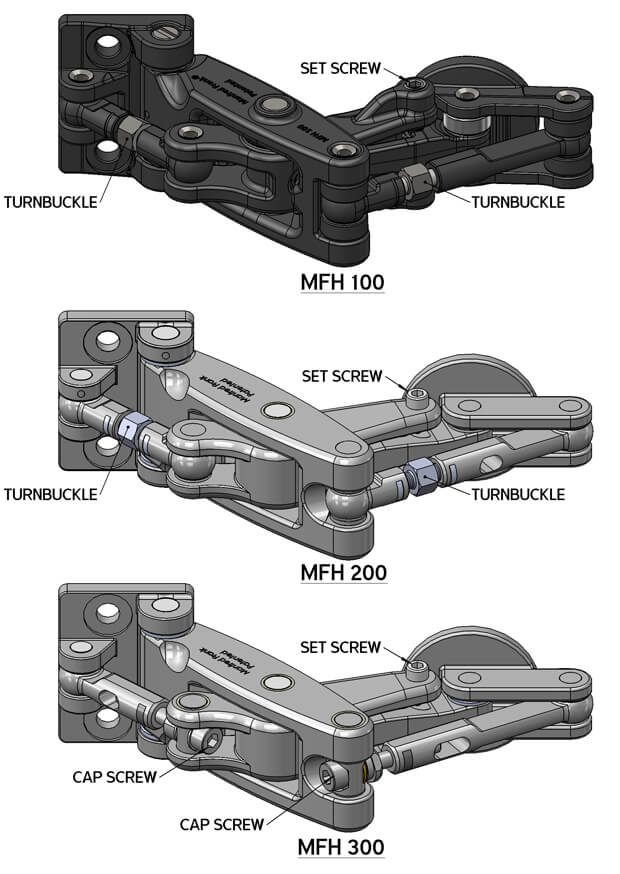

Mechanisms

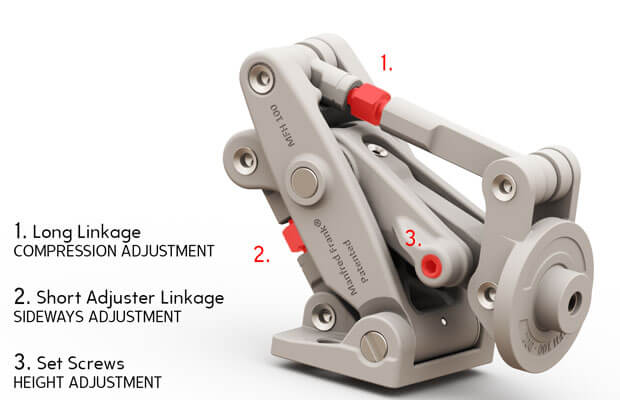

Each plane of adjustment has its own specific mechanism.

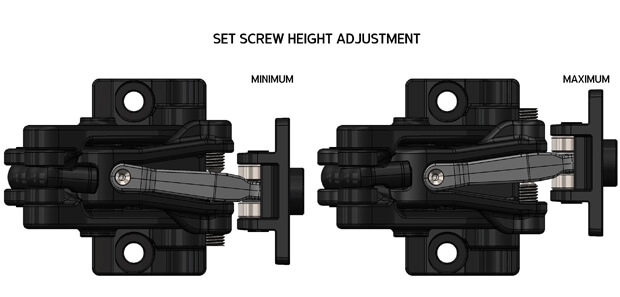

Set Screws Set screws are used to modify the height in all hinge models. Two opposing screws hold the height adjustment arm in the required position. The standard tool required is a 4mm Hex Ball Nose Allen Key.

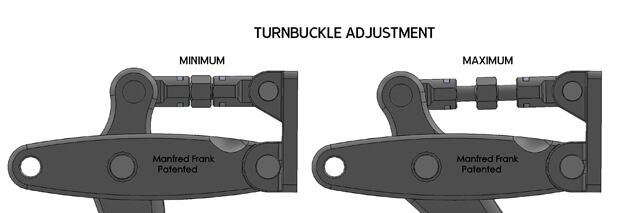

Turnbuckle Linkage The turnbuckle linkages feature a left and right handed thread, which are used to adjust the sideways and compression locations of the hinge. Turnbuckles are adjusted using a simple 11mm Open Ended Spanner.

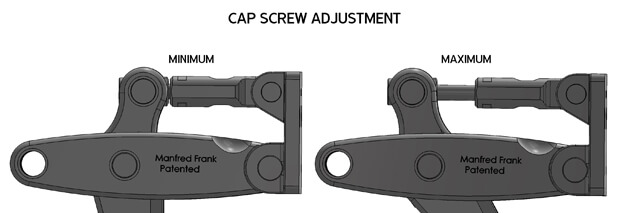

Cap Screw Linkages Cap screw linkages are used in the place of turnbuckles where accessibility is restrictive and spanners are inappropriate. The standard tool required is a 5mm Hex Ball Nose Allen Key (preferably in a T Bar configuration).

Adjustment Process

Hinge adjustment is easily achieved with just two steps:

1. Once mounted, the first hinge adjustment to make is to set the correct height position. To do this, unscrew the uppermost set screw as this will allow the height adjustment arm to move. After this, turn the lower set screw until the desired height is reached. Finally, turn the upper set screw down to hold the height adjuster arm back in place.

2. The next step is to manipulate both the sideways and compression linkages until the panel is aligned. When adjusting the length of a linkage there might be a slight crossover effect on the other linkage. For example when adjusting the panel compression it might be necessary to compensate for the crossover effect on the sideways linkage. Thus, aligning the panel is a quick and simple process of refinement. Check it out in action here.

JOB DONE!

As you can see, the adjustment process is fairly simple. It can be easily completed by one person without the need for special training, tools or equipment. Furthermore, it is achieved after the hinges are installed when they are under full load. Perfect panel alignment is easily accomplished and will last a lifetime.

Future proofing

Manfred Frank hinges are built to last. The patented principle incorporating self locking adjustment mechanisms ensures permanent perfect panel alignment. Manfred Frank offers a GUARANTEE -NO LOSS OF ADJUSTMENT for the life of the hinge. Any future alignment changes due to building or frame structure settling will only require two basic tools and just moments of a single person’s time. No lifting or supporting equipment is needed.